Fanchi Fully Auto packaging machine can be equipped with a net weight or gross weight weighing system. According to the characteristics of the material, the feeding method can be divided into self-falling + vibration feeding, free-falling, belt or screw conveying. It has strong adaptability and can use various types and specifications of packaging bags. The replacement of different specifications of packaging bags can be completed in a short time by the touch screen.

Introduction

Fanchi fully automatic packaging machine fills, packages and seals weighed materials. The bag taker of the automatic bag loading machine sucks the empty bags in the first stack on the bag feeding device through a vacuum suction cup and lifts them up. The empty bags are clamped and dragged to the support platform of the bag loading machine through the claw cylinder of the gripper. Center the empty bag to the central position through the bag centering cylinder, and then send the empty bag to the position of the upper bag manipulator through the front pressure wheel of the bag feeder. If the empty bag is in place normally, the bag opening of the upper bag machine will be sucked. Open, bag loading robot. After the inserting knife is inserted, the gear clamp of the bag loading manipulator clamps the empty bag. When the bag delivery trolley clamps the full bag and lowers it into place, the manipulator will push the empty bag to the bag clamp device, and the bag clamp clamp and splint will clamp the empty bag. After the bag is clamped, the bag is judged: whether it is set properly. When the packaging bag is set, the bottom door of the electronic scale will be opened to load the material into the bag clamp device; when the bag is judged to be not set properly, the bag will be blown out through the nozzle of the bag blowing system. Blow off. When the filling is completed, the splints and holding plates of the bag delivery trolley clamp the bag mouth and hug the bag body respectively. After the splints descend, the full bags are sent to the introduction device and the sewing conveyor through the long package delivery cylinder. The synchronous belt of the introduction device The bag mouth is clamped and the collaborative conveyor sends the full bag into the folding and sealing system. After folding and sealing, the full bag enters the palletizing process.

Features and Advantages

1. The feeding mechanism combined with the arch breaking device, satisfies the packaging of materials with highly differentiated characteristics, and is suitable for the use of granules and powders on the same packaging machine;

2. The size of the material door is controlled by the servo motor, which is convenient for adjustment and is suitable for the use of products with multiple specifications;

3. The weighing device adopts a three-sensor suspension mechanism to ensure the accuracy of the weighing;

4. The solid device, after filling the bag, makes the material in the packaging bag denser through solid action, and at the same time the material on the inner wall of the channel falls into the packaging bag;

5. Fully automatic sewing machine, with automatic sewing, thread cutting, thread breaking and shutdown functions, and fast switching sewing and heat sealing functions.

Technical Specifications

Product model | FA-PM-Z50 |

Overall dimensions | 5160*3415*3860mm |

Packaging speed | 500-600bag/h |

Weighing range | 10-50KG |

Tolerance | ±10~50g |

Equipment weight | 5T |

Packing Bag Material | Non-breathable, non-heat-cut woven bags, plastic bags, paper bags, non-woven bags, etc |

Machine material | The material contact part is made of 304 stainless steel, while the others are made of carbon steel |

Rated voltage | 220v/380v |

Installed power | 10KW |

Adapt to the environment | Temperature: - 10~+50 ℃; Humidity 30~70% |

Applicable materials | Granular/Powder |

Barometric capacity | 0.5~0.6MPa 0.36m ³/ min |

| Tolerance scope | ±40~200g |

Application

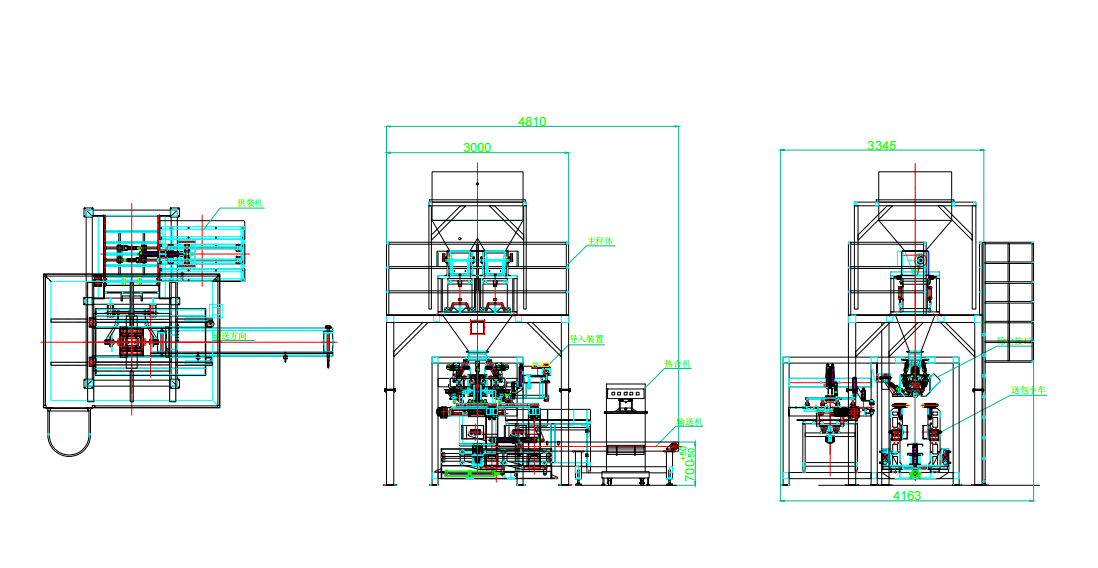

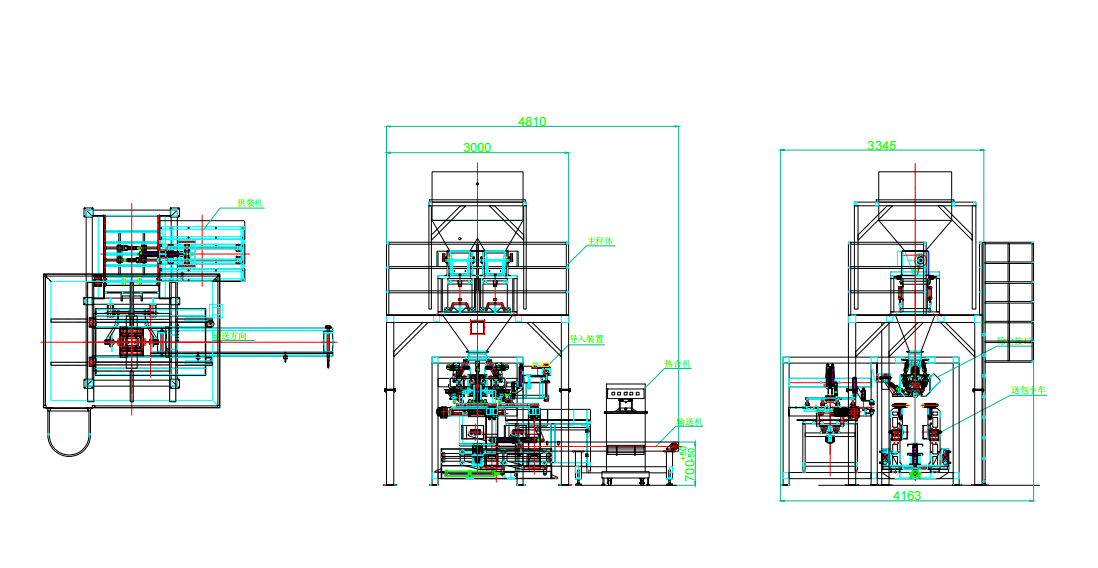

CAD Drawing

CAD Drawing

Introduction

Fanchi fully automatic packaging machine fills, packages and seals weighed materials. The bag taker of the automatic bag loading machine sucks the empty bags in the first stack on the bag feeding device through a vacuum suction cup and lifts them up. The empty bags are clamped and dragged to the support platform of the bag loading machine through the claw cylinder of the gripper. Center the empty bag to the central position through the bag centering cylinder, and then send the empty bag to the position of the upper bag manipulator through the front pressure wheel of the bag feeder. If the empty bag is in place normally, the bag opening of the upper bag machine will be sucked. Open, bag loading robot. After the inserting knife is inserted, the gear clamp of the bag loading manipulator clamps the empty bag. When the bag delivery trolley clamps the full bag and lowers it into place, the manipulator will push the empty bag to the bag clamp device, and the bag clamp clamp and splint will clamp the empty bag. After the bag is clamped, the bag is judged: whether it is set properly. When the packaging bag is set, the bottom door of the electronic scale will be opened to load the material into the bag clamp device; when the bag is judged to be not set properly, the bag will be blown out through the nozzle of the bag blowing system. Blow off. When the filling is completed, the splints and holding plates of the bag delivery trolley clamp the bag mouth and hug the bag body respectively. After the splints descend, the full bags are sent to the introduction device and the sewing conveyor through the long package delivery cylinder. The synchronous belt of the introduction device The bag mouth is clamped and the collaborative conveyor sends the full bag into the folding and sealing system. After folding and sealing, the full bag enters the palletizing process.

Features and Advantages

1. The feeding mechanism combined with the arch breaking device, satisfies the packaging of materials with highly differentiated characteristics, and is suitable for the use of granules and powders on the same packaging machine;

2. The size of the material door is controlled by the servo motor, which is convenient for adjustment and is suitable for the use of products with multiple specifications;

3. The weighing device adopts a three-sensor suspension mechanism to ensure the accuracy of the weighing;

4. The solid device, after filling the bag, makes the material in the packaging bag denser through solid action, and at the same time the material on the inner wall of the channel falls into the packaging bag;

5. Fully automatic sewing machine, with automatic sewing, thread cutting, thread breaking and shutdown functions, and fast switching sewing and heat sealing functions.

Technical Specifications

Product model | FA-PM-Z50 |

Overall dimensions | 5160*3415*3860mm |

Packaging speed | 500-600bag/h |

Weighing range | 10-50KG |

Tolerance | ±10~50g |

Equipment weight | 5T |

Packing Bag Material | Non-breathable, non-heat-cut woven bags, plastic bags, paper bags, non-woven bags, etc |

Machine material | The material contact part is made of 304 stainless steel, while the others are made of carbon steel |

Rated voltage | 220v/380v |

Installed power | 10KW |

Adapt to the environment | Temperature: - 10~+50 ℃; Humidity 30~70% |

Applicable materials | Granular/Powder |

Barometric capacity | 0.5~0.6MPa 0.36m ³/ min |

| Tolerance scope | ±40~200g |

Application

CAD Drawing

CAD Drawing